Can advanced oxidation technology help control TOC in semiconductor water?

Date Published 2017 | UPW journal archive

Log in or Join UltraFacility to access this content

To access our resources you will need to be a member of UltraFacility, log in to your account or purchase a membership to view this content.

Already have an account? Log in

This article will discuss typical organic removal methods commonly applied in a semiconductor ultrapure water (UPW*) system and new methods for improving the removal of organic contaminants from the critical process water. An equipment manufacturer has developed an advanced oxidation processes that specifically addresses total organic carbon (TOC) levels, to reduce them to sub-part-per-billion (ppb) levels. This has been shown to have significant benefits in the integrated chip (IC) manufacturing process

Organizations: Evoqua Water Technologies

Tags: Total Organic Carbon (TOC)Advanced OxidationUPW

Related content

Learning series | 2018

End-of-Pipe Semiconductor Wastewater Reclaim

Conference material | 2022

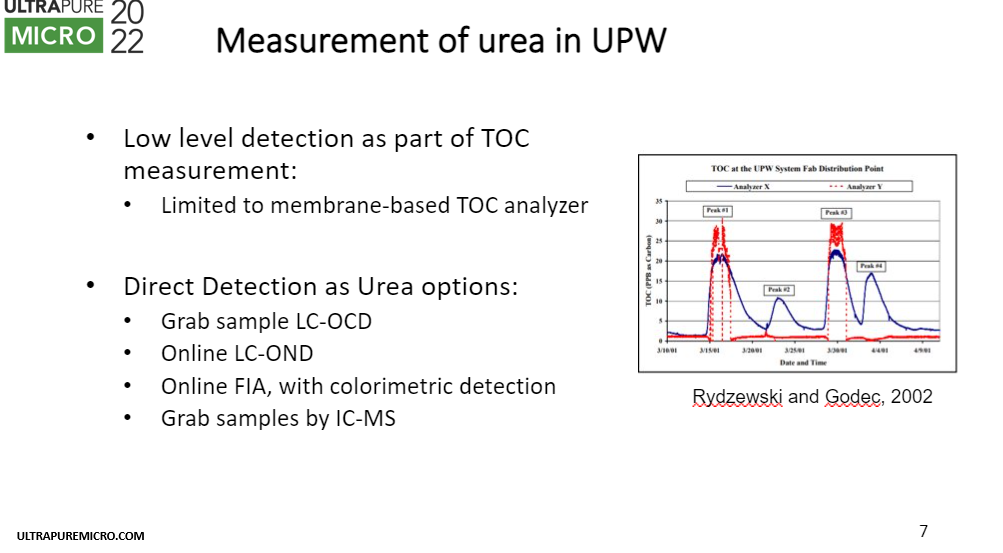

What is Known About Urea Control in UPW Systems?

Conference material | 2018

U-PURTM – A Metal-Free Combination of Several UPW Polishing Steps in a Multifunctional Reactor for the Removal of TOC and H2O2 Traces

Conference material | 2022

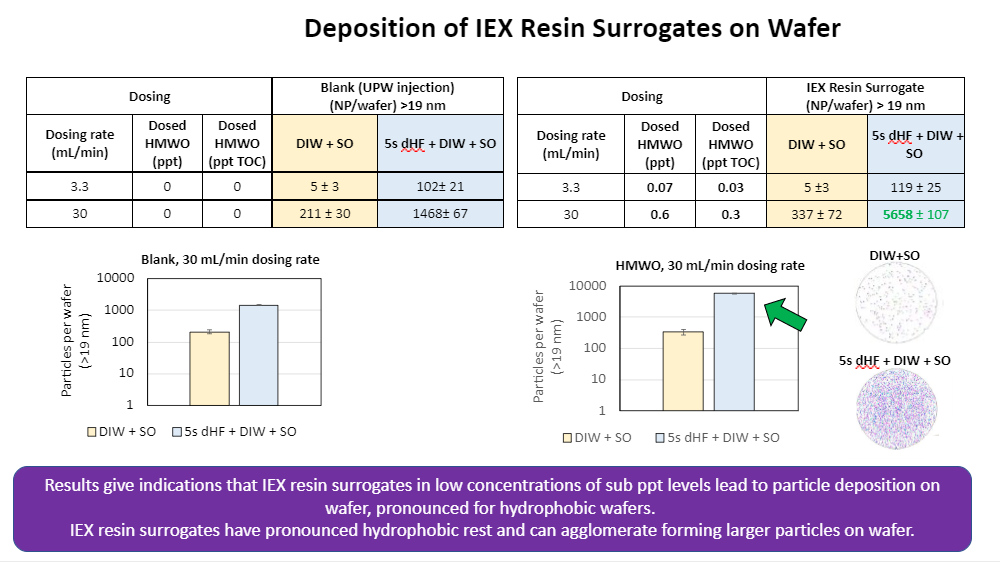

Establishing Correlations between UPW Quality and Particle Deposition on Silicon 300 mm Wafer

Back to results