Development of H₂O₂ monitor most suitable for UPW polishing system

Date Published 2018 | UPW journal archive

Log in or Join UltraFacility to access this content

To access our resources you will need to be a member of UltraFacility, log in to your account or purchase a membership to view this content.

Already have an account? Log in

A newly developed H2O2 monitoring method is capable of continuous measurement without using chemical reagents but catalase-resin instead. This technology also makes it possible to measure H2O2 that is generated in a UV-ox (ultraviolet oxidizer) without interference. This study was conducted to support an ultrapure water (UPW) polishing system, and to compare existing H2O2 monitoring procedures with the new technology. This article was originally published in the Ultrapure Micro Journal in February 2018.

Organizations: Nomura Micro Science

Authors: Yukio Noguchi, Tags: UPW PolishingUltraviolet (UV)Metrology and Analytical TechnologyHydrogen Peroxide (H2O2)

Related content

Conference material | 2018

Development of an Online Urea Monitor for Ultrapure Water Production in Semiconductor Fabrication Plants

Conference material | 2022

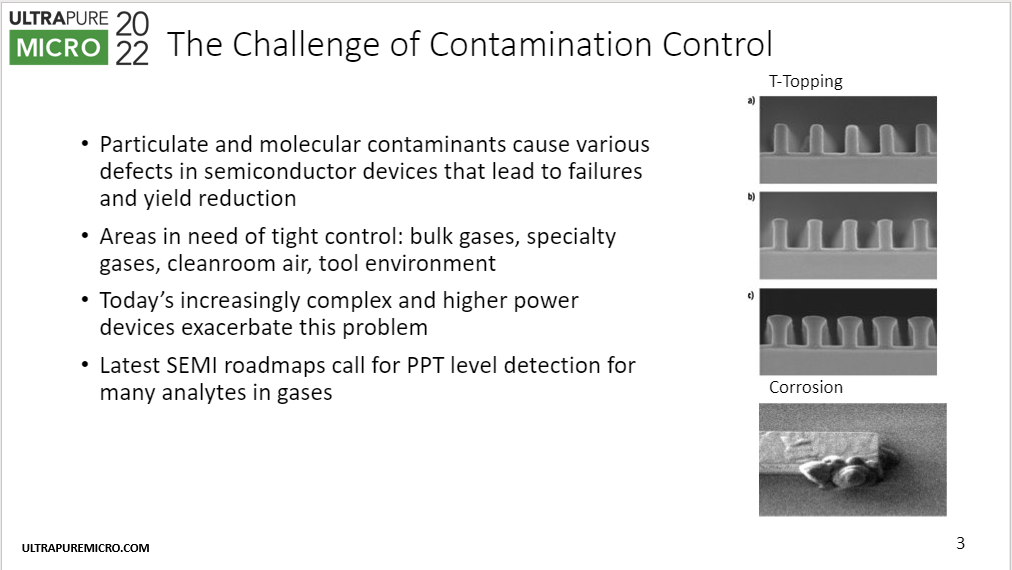

Multi-Species PPT-Level Impurity Detection in Electronic Bulk Gases Using Atmospheric Pressure Ionization Mass Spectrometry

Conference material | 2015

THM – A Novel Sustainable Approach as a Global Solution for UPW Applications

Conference material | 2020

Determine functional pore sizes of ultrafiltration membranes by nanoparticle retention test using single particle ICP-MS

Back to results