IRDS and SEMI Standards Enabling Yield by Wet Processing Defect Control in Advanced Semiconductor Technologies

Date Published 2018 | Conference materials

Log in or Join UltraFacility to access this content

To access our resources you will need to be a member of UltraFacility, log in to your account or purchase a membership to view this content.

Already have an account? Log in

This presentation was given at the Ultrapure Micro 2018 annual conference. It was presented as a Keynote presentation.

Organizations: FTD Solutions

Tags: IRDSSilicaSEMIRisk ManagementParticles

Related content

Conference material | 2021

Risk centered asset management

Learning series | 2017

Ion Exchange Resins - How They Work, Why They Work and How They Don't Work

UPW journal archive | 2013

Semiconductor Industry Trends Highlighted at UPW Micro 2012

Conference material | 2021

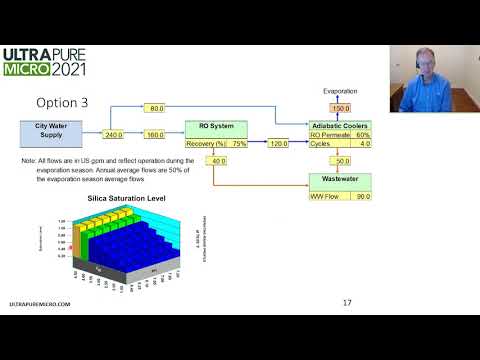

Doing more with less - minimizing data center water and wastewater

Back to results