Keynote Panel: Yield and Reliability- Enabling Advanced Semiconductor Yield

Date Published 2022 | Conference materials

Log in or Join UltraFacility to access this content

To access our resources you will need to be a member of UltraFacility, log in to your account or purchase a membership to view this content.

Already have an account? Log in

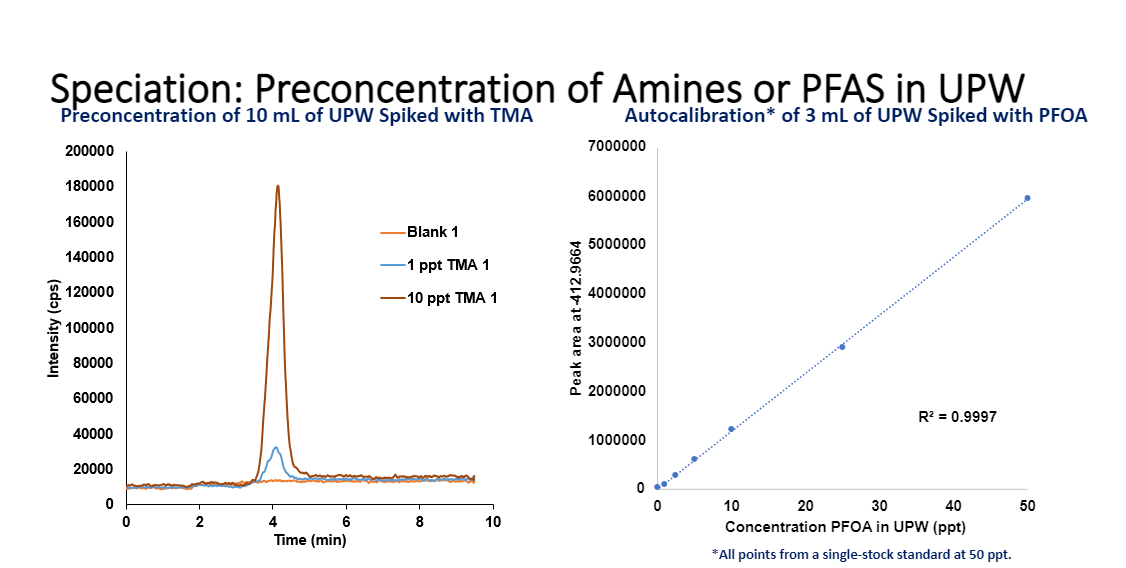

A discussion of how contamination and defectivity control might be done differently in the future, to enable advanced semiconductor yield.

Tags: YieldWafer DefectivityEnd-userOrganic Contamination

Related content

Conference material | 2018

Development of an Online Urea Monitor for Ultrapure Water Production in Semiconductor Fabrication Plants

Conference material | 2021

Risk centered asset management

Conference material | 2022

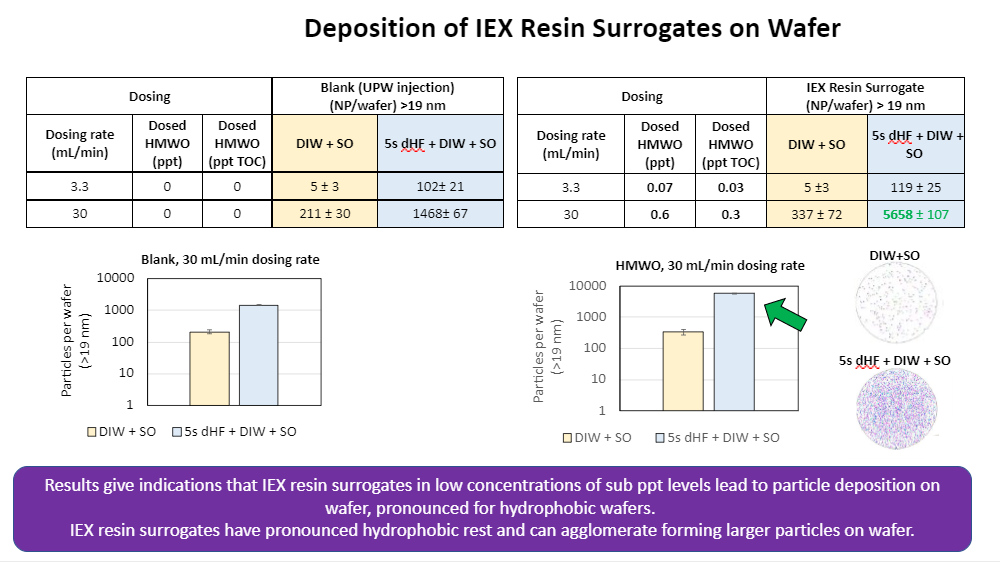

Establishing Correlations between UPW Quality and Particle Deposition on Silicon 300 mm Wafer

Conference material | 2022

Online Automated Determination of Organic Contaminants in Semiconductor Grade Chemicals

Back to results