Gerd Heser

Application Manager UPW & Systems

Pall

Jochen Ruth

Senior Manager SLS

Pall

Collaborators

Tags

Silicon CarbideFiltrationWater reclamation and reuseChallenges of SiC-Containing Wastewater

Share this insight

Ultrapure Micro 2023 started with a big surprise for Pall. We won the best presentation award in the Environmental Sustainability strand for last year’s contribution entitled “The Value of Wastewater”. This, of course, set the benchmark high as we had a presentation scheduled for a similar topic – the 2023 presentation also concerned a reclaim concept, but differently, it targeted silicon carbide (SiC) processes.

SiC is gaining a lot of traction and several new plants have been announced or already under construction. The driver is clearly electric mobility. There is rapid expansion going on a global perspective for power semiconductors for electric vehicles. As SiC is the second hardest material known and extremely chemically inert, it is necessary to investigate the technology transfer from the well understood silicon (Si) based substrates to the new SiC substrates, to ensure efficient manufacturing.

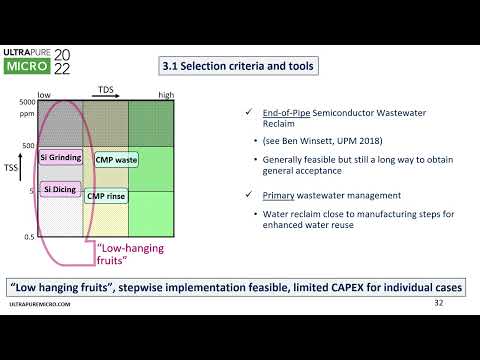

The process steps which include mechanical grinding, dicing and shaping the raw SiC ingot, which is also called a boule or a puck, offer a good example for systematic process technology selection for SiC containing wastewater effluent.

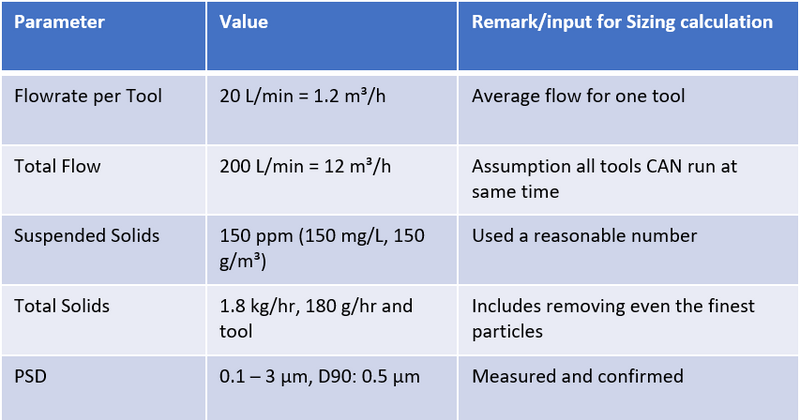

Table 1 shows fluid consumption and solids characterization, from which key decision points can be derived.

Table 1: Fluid and solid properties

A treatment tool for this kind of waste could be either located close to every tool or a smaller grouping of tools, or as a centralized treatment unit in a less sensitive area outside the cleanroom.

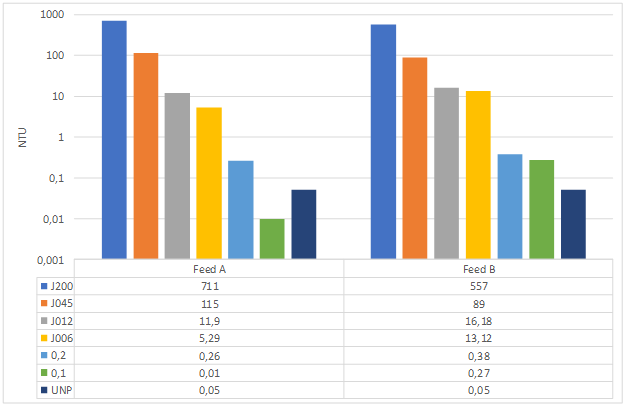

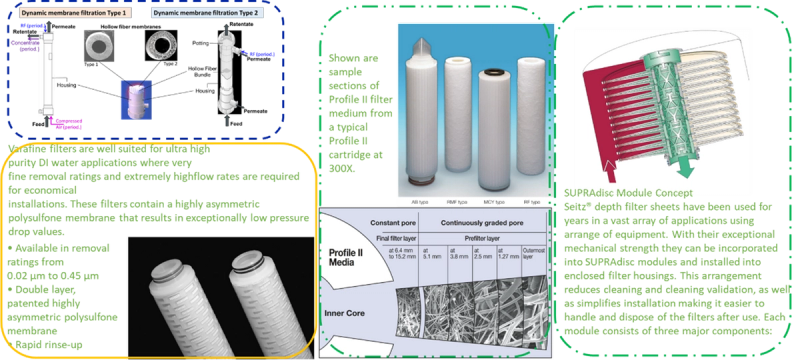

Detailed investigation of filter efficiency to remove the suspended particle load revealed that a cascade of disposable filters with minimum rating at 0,2 µm for the final stage is needed. Alternatively, a dynamic membrane filtration (DMF) concept could be applied, removing even the finest particles in one step.

Figure 1: Filtrate quality by NTU (Nephelometric Turbidity Units) from disposable and DMF filters

Developing full-scale solutions from these data and boundary conditions may lead a process technology engineer to 2 very different solutions:

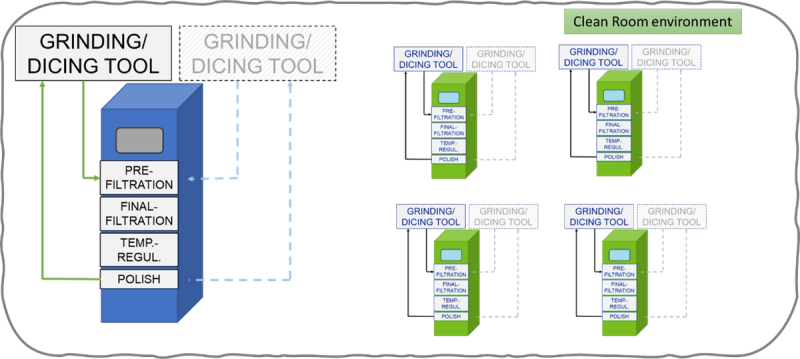

1. Decentralized individual treatment units, duplicating all necessary filtration and conditioning steps located in the cleanroom

2. Centralized treatment system with filtration and conditioning in a much larger size, located outside of cleanroom

Figure 2: Decentralized multiple treatment units

Figure 3: Decentralized fully-automated treatment system

Figure 4: Available Filtration Types.

To summarize, treating wastewater effluent from SiC disintegration processes can be achieved with a decentralized multiple unit approach. With this approach, footprint and maintenance access will consume cleanroom space and workforce.

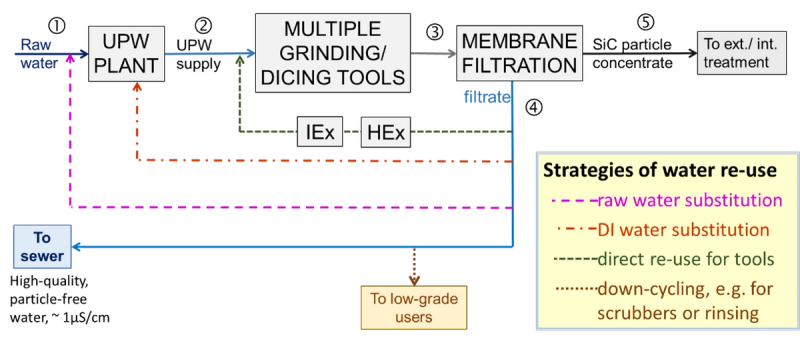

Alternatively, a centralized treatment can be installed in the sub fab. The decision for centralized or decentralized solutions depends on flow rate and concentration of suspended solids. A centralized unit becomes a more attractive option for reclaiming this wastewater when the flow is higher and there is a greater concentration of solids. The water is chemically not contaminated and the reclaimed water is very near to deionized (DI) water quality – as such it is definitely much cleaner than any raw water source.. Naming the reclaim ‘wastewater’ is quite misleading as the water has a high degree of cleanliness, and therefore it is very valuable.

The current performance data from pilot systems are very encouraging and demonstrate reliable removal of all suspended particles and a very stable level of trace contamination kept in this quasi closed-loop installation.

The above content was presented this year entitled “Systematic Process Technology Selection for treating SiC containing Waste Water”. Another time Ultrapure Micro manifested its status of the go-to conference for any facility driven and process fluid cleanliness or reclaim technologies and concepts.

We experienced a lively Q&A session with some of the industry’s key stakeholders, and the conversations continued in the networking sessions after the presentation and days after. We are looking forward to attending and contributing to Ultrapure Micro 2024. Stay tuned.

View the slides and recording for this presentation on the UPM Technical Knowledge Base.

View the other winners of the best presentation awards in the insights hub.

Share this insight

Related insights

Expert Q&A – Driving Yield and Reliability Solutions in the Semiconductor Industry

Orla McCoy

Global Water Intelligence

Onsite Water Reuse and Recovery Roundtable Insights

Orla McCoy

Global Water Intelligence

Sustainable water treatment technology: trends and challenges

Orla McCoy

Global Water Intelligence

Related resources

Systematic Process Technology Selection for treating SiC containing Waste Water