Orla McCoy

Global Water Intelligence

Collaborators

Tags

SEMI StandardsConstructionGasesEnergy ConservationChemicalsPFASSustainabilityWater ConservationYield enhancementMarket TrendsYear-in-review: UPM Community Events 2022

In 2022, the UPM Community came together in eight online meetings in order to continue conversations year-round – in addition to the in-person conference in Phoenix, Arizona. Here are summaries and materials from all the UPM Community online meetings of 2022.

Share this insight

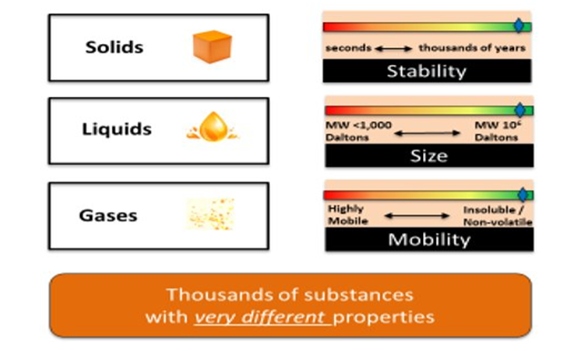

1. Kicking off the year, the UPM Community concentrated on an extremely hot topic for wastewater and high-purity components in the meeting 'PFAS: Upcoming Regulations and the SEMI Industry Response'. Experts explained the criticality of understanding the different properties of different PFAS – as shown by the chart below – as well as some key action points for the industry.

Speakers from Intel, Chemours, Georg Fischer, GHD, GF Piping Systems, Kinetics, and Enviro-Energy Solutions.

Source: Chemours

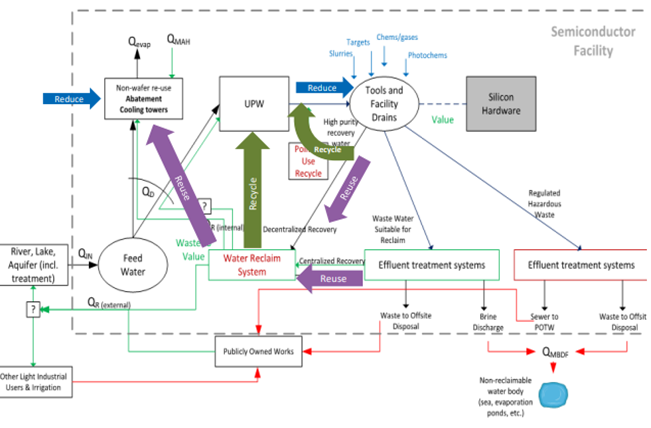

2. Embarking deeper into environmental sustainability topics, the next UPM Community Event focused on how to reduce, reuse and recycle water across semiconductor facilities. After opening remarks on sustainable water usage from Paul Kerr, Environmental Technologist at Intel, event attendees then split into interactive roundtables to discuss different technologies and best known practices. Find roundtable handouts in the Community Event Resource Hub or read an event summary highlighting four key themes discussed by roundtable leads.

Source: Intel

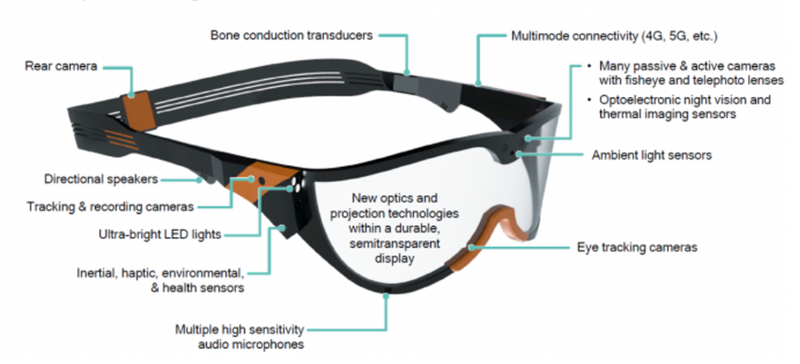

3. Changing gears in April, the UPM Community explored Yield and Reliability Drivers as part of the ‘Deconstructing the Challenges of Facility 2.0’ series. This first event unveiled how new semiconductor technology drives chip purity requirements; factory integration needs; and opportunities for increasing yield via big data. The AR glasses below show just one example of the complex digital products which require new, sophisticated semiconductor technology. Speakers from Qualcomm, Tokyo Electron, Page/, and FTD Solutions.

Source: Qualcomm

4. With increasing complexity for facilities, how can the industry ensure they have enough trained talent to continue their operations? The next event of the series, Expertise in Semiconductor Facilities Operations revealed that a singular semiconductor facility in Arizona will require an additional 180 personnel in general facilities roles in the following 18 months. Why did the semiconductor facility expertise shortage come about, how are different companies affected, and what solutions can be offered? Answers were offered by speakers from Intel, SCREEN, Page/, Environ-Energy Solutions, and Arizona State University.

Source: Intel

5. Industry resources were also a hot topic of conversation in the meeting Time-to-market and Supply Chain in the Microelectronics Industry. Speakers discussed how the industry is facing a ‘perfect storm’: The complexity of mega campuses challenges the schedule to bring new fabs online, as facilities must be interconnected with the rest of the campus. At the same time, lead times are unprecedentedly long - as shown by the contracted vs actual schedules shown below. How can the industry ramp up to meet chip demand? Solutions were offered by speakers from Intel, LotusWorks, Evoqua Water Technologies and FTD Solutions.

6. How can the industry sustain itself in the face of multiple simultaneous transformational changes? In July, the UPM Community had a compelling discussion about Environmental and Operational Sustainability. Unprecedented demand for semiconductor products leads to the construction of fabs which are larger and more complex than ever before. The fabs also consume increasing quantities of energy, water, chemicals, and other materials. At the same time, sustainability goals are becoming a very real priority for chipmakers. Methods of sustaining industry operations were discussed by speakers from Applied Materials, GF Piping Systems, and FTD Solutions.

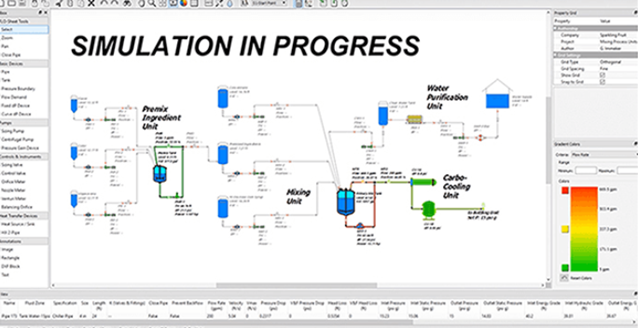

7. Not only do these more complex facilities consume more water and energy, but greater chemical and gas volumes are also required. The next UPM Community Event, Device Complexity Drives Facility Complexity explained why the production of device drivers complicate facility construction and management issues for these materials. Below is an example of some of the digital processes which aid the management of such complexity. Speakers from Samsung Austin Semiconductor, Page/, Farnsworth Group, and Hensel Phelps.

Source: Samsung Austin Semiconductor

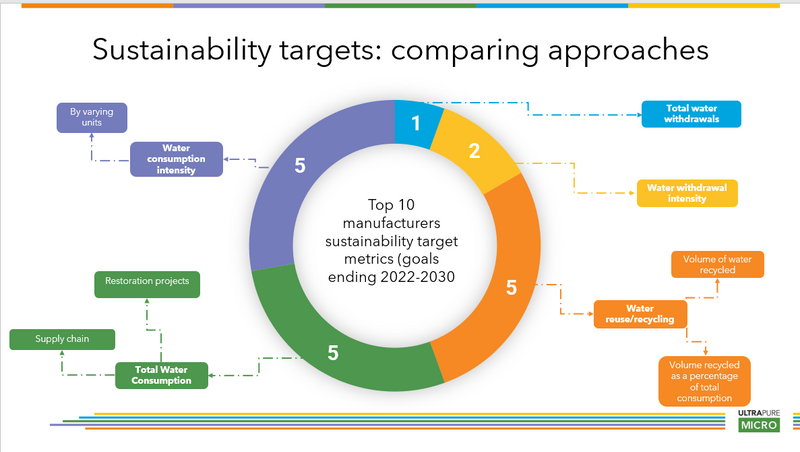

8. Finally, the UPM Community finished off the year with a look to the future: The Microelectronics Industry in 2023: A drive towards sustainability, reuse, and growth in water-related spending. How do market dynamics effect microelectronics industry water spending? Can we begin to analyze different approaches taken by end-users? Which technologies can take water reuse to the next level? Speakers from Global Water Intelligence provided insights.

Source: GWI

Share this insight

Related insights

News-in-Brief: January 2024

Q&A Results with ElectraMet: Copper recovery from CuCMP Wastewater

Cameron Lippert

Electramet

The Rising Tide of CEDI: Why it is Outshining Traditional Ion Exchange in High-Purity Applications (Part 2)

Orla McCoy

Global Water Intelligence